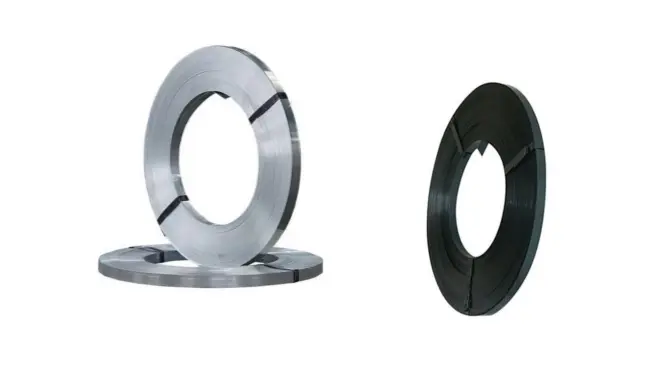

What is Heavy Duty Steel Strapping?

Heavy-duty steel strapping is manufactured from high-carbon cold-rolled steel. It undergoes a specialized heat-treatment process—often referred to as High Tensile—to ensure it can absorb impacts without snapping.

Key Characteristics:

- High Break Strength: Capable of holding loads ranging from 2,000 lbs to over 15,000 lbs depending on width and thickness.

- Minimal Elongation: It doesn’t stretch significantly, making it ideal for “dead” loads (like bricks or steel beams) that don’t settle or shrink.

- Heat Resistance: Essential for use in foundries or on products that are still hot from production.

- UV and Chemical Resistance: Unlike polymers, steel does not degrade under intense sunlight or exposure to harsh industrial chemicals.

Technical Specifications (Typical)

While dimensions vary by manufacturer, heavy-duty strapping typically falls into these common ranges:

| Width (inches) | Thickness (inches) | Tensile Strength (lbs) |

| 3/4″ | 0.025 – 0.031 | 2,300 – 3,500 |

| 1-1/4″ | 0.029 – 0.035 | 5,500 – 6,750 |

| 2″ | 0.044 – 0.050 | 12,000 – 15,000+ |

Common Applications

Steel strapping is the backbone of heavy industry. You’ll find it utilized in:

- Steel Service Centers: Bundling steel coils, pipes, and rebar.

- Construction: Securing crates of heavy stone, brick palates, and lumber.

- Rail & Shipping: “Secondary Securement” to prevent shifting in railcars or ocean containers.

- Manufacturing: Holding heavy machinery components to transport skids.

Safety and Equipment

Because steel strapping is under high tension and has sharp edges, it requires specific tools and safety protocols.

Tools Required:

- Tensioner: Manually or pneumatically tightens the strap around the load.

- Sealer (Crimper): Compresses a steel seal onto the overlapping strap ends.

- Shears: Specialized cutters designed to cut through high-tensile steel safely.

Pro-Tip: Always use “Safety Shears” that hold one end of the strap down during the cut. This prevents the “whiplash” effect, which can be dangerous when the tension is released.